Timber Window Manufacturers

Discover the Superior Benefits of Vacuum Insulated Glass (VIG) for Timber Windows

Welcome to the Timber Window Manufacturers page, where we explore the incredible benefits of using vacuum insulated glass in timber window applications. NuGen Glass offers a revolutionary solution that combines cutting-edge vacuum glass technology with exceptional energy efficiency, making it the ideal choice for various timber window projects.

Ideal Vacuum Glass Product: Optimum

Perfect for future build projects where energy efficiency and soundproofing are a priority without having to meet strict passive house standards.

Addressing your specific needs

But what about the specific details that matter to you as Timber Window Manufacturers? Let’s address them:

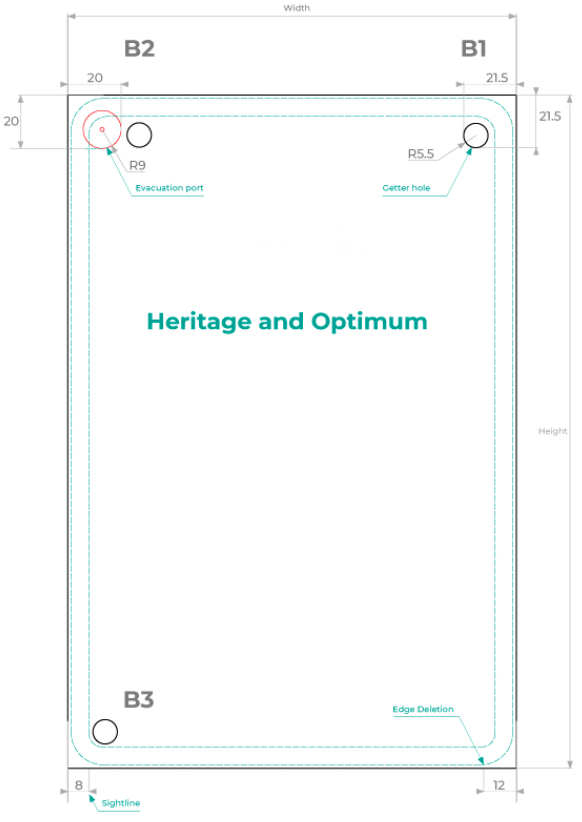

- What about the plugs and getters

- In Heritage and Optimum units, plugs and getters are located within a 20mm border around the unit. These components are concealed within a standard glazing rebate, offering a sleek appearance. On smaller units, the aligning of getters and plugs along the same horizontal edge enables shuffle glazing to completely hide them, further enhancing window performance.

- Micro-Pillars

- Commonly known as “the dots,” these micro-pillars prevent glass panes from touching under the high vacuum pressure. Vacuum glass advanced technology ensures significantly fewer micro-pillars compared to other vacuum glazing options. Moreover, the coloration of the pillars makes them inconspicuous, rendering them virtually invisible when viewed from a standard distance of 2m.

- Benefits over slim double-glazing

- While slim double glazing may have served its purpose in the past, the industry is rapidly progressing toward higher sustainability and energy conservation expectations. Slim double glazing falls short in terms of heat retention, exhibits double reflection even in the slimmest units, and has shorter lifespans with higher breakdown rates. By embracing our vacuum glazing, you position yourself at the forefront of these advancements.

- Glass weight and window design

- As energy efficiency requirements increase, manufacturers seek more efficient glass units. However, adding more glass panes and cavities results in a substantial increase in weight per square meter. This weight, combined with the market’s demand for increased glass sightlines and larger pane sizes, poses challenges for manufacture and installation. Ironmongery systems struggle to keep pace with these changes, leading to potential reductions.

- Maximum and minimum unit sizes

- The maximum unit size 1500mm x 2500mm. Vacuum glazing units are actually more rigid than typical double glazing due to the vacuum, but as units get larger they may be made using thicker glass panes. The minimum unit size is typically 300mm x 300mm, but smaller sizes can often be made on demand. The minimum unit size for pricing is 0.3m2.

- Shaped glass units

- Vacuum glass is available in a variety of shapes. The maximum width to Height ratio 1:6 for 8.3mm, if the ratio is any larger then it will need to be 10.3mm. Any shape with a right angle and single point of radius is possible. Isosceles triangles or right-angled triangles with a hypotenuse greater that 370mm are also possible. In all cases, CAD drawings must be supplied for any shape orders. If you aren’t sure, then just ask!

Our Products

How does Vacuum Glazing compare to the most popular options?

The Solution for all Timber window manufacturers: Vacuum insulated glass (VIG)

Enhancing Performance and Aesthetics: Unleashing the potential of 0.4 centre pane U-value vacuum glass for timber window manufacturers.

Discover how vacuum glass can enhance the performance and aesthetics of your window installations in three key areas:

Heritage Windows

Preserving the charm of Listed and conservation properties while improving energy efficiency is now possible with Heritage vacuum glass. Its ultra-slim profile and single reflection make it the perfect choice for heritage window frames. Say goodbye to cold and expensive-to-run listed properties as vacuum glass brings them up to modern standards of energy efficiency.

High Performance Windows for Renovations and New Builds

Heritage vacuum glass enables manufacturers to achieve remarkable window U-values of 1.0 – 1.2 W/m²K, ensuring compliance with future Part L regulations. This lightweight and sustainable solution outperforms triple glazing, reducing materials usage and enhancing recyclability.

Extreme Performance Windows for Futurebuild Projects

Experience the future of window performance with Optimum vacuum glass. Achieve outstanding whole window U-values of 0.8 – 1.0 W/m²K by converting standard double-glazed profiles. This innovative solution exceeds upcoming Part L regulations, offering exceptional energy efficiency without bulky frames or quad glazing. Optimum vacuum glass ensures optimal performance and Part Q compliance for new builds.