Which is the best glass for sound reduction

When you have had a long day, there is nothing better than being able to close the door and enjoy the peace and quiet. If you live in a busy and vibrant part of the world, then you will certainly understand the importance of noise reduction in windows and doors. In this blog, we will explore which is the best glass for sound reduction and review whether vacuum glazing units have an important role to play in this arena. We also refer to sound reduction as either noise reduction or acoustic performance.

How do you assess Acoustic Performance?

Acoustic performance levels are expressed using the index Rw (C; Ctr) shown in decibels (dB). Rw is a weighted balance which can be used to categorise products and provide direct comparisons. A higher number represents a higher percentage reduction of the noise frequency. Occupants will typically perceive approximately a 50% reduction in noise transmission for every 10dB improvement in acoustic value.

Specifying the best glass for sound reduction

Soundproof glazing works by deflecting and dissipating sound waves. There are a few factors which determine how effective a glass unit is at reducing noise:

Pane Thickness

Thicker panes perform better than thin panes for sound attenuation. Also, a combination of different thickness panes, formed into a glazing unit, will perform better than two equal panes. This is why a lot of acoustic glass specifications are designed with a 6.4mm and an 8.8mm pane.

Pane Number

One pane of glass will perform less well than two panes of glass. The reason is that the two panes interrupt different parts of the sound wave as it passes through the glazing unit. For the same reason, three panes will perform better than two panes.

Cavity Space

The larger the gap between the panes of glass the better acoustic performance. Triple glazing adds another layer of air which further reduces the sound passing through the unit.

Interlayers

Laminated glass has a thin layer of polyvinyl butyral (PVB) sandwiched between two panes of glass. PVB interlayers provide additional acoustic performance by dampening soundwaves and there are specialist PVB interlayers designed specifically for acoustic performance. A laminated pane is made from two individual thinner panes of glass, so there is benefit from the pane number as well.

Cavity Fill

This is a relatively new consideration, as typically the gas fill in a cavity has only marginal impact on the acoustic performance of the glass. However, with the introduction of vacuum glazing, this becomes a factor. As you may already know, sound doesn’t travel in a vacuum – sound is just vibrating air, space has no air to vibrate and therefore no sound.

The best possible glass unit for sound reduction would be quad glazed, with four different thicknesses of glass panes containing interlayers and three different thickness vacuum cavities. Of course, a glass unit like this would be completely impractical in terms of weight, overall thickness and price; so we need to take a more balanced approach.

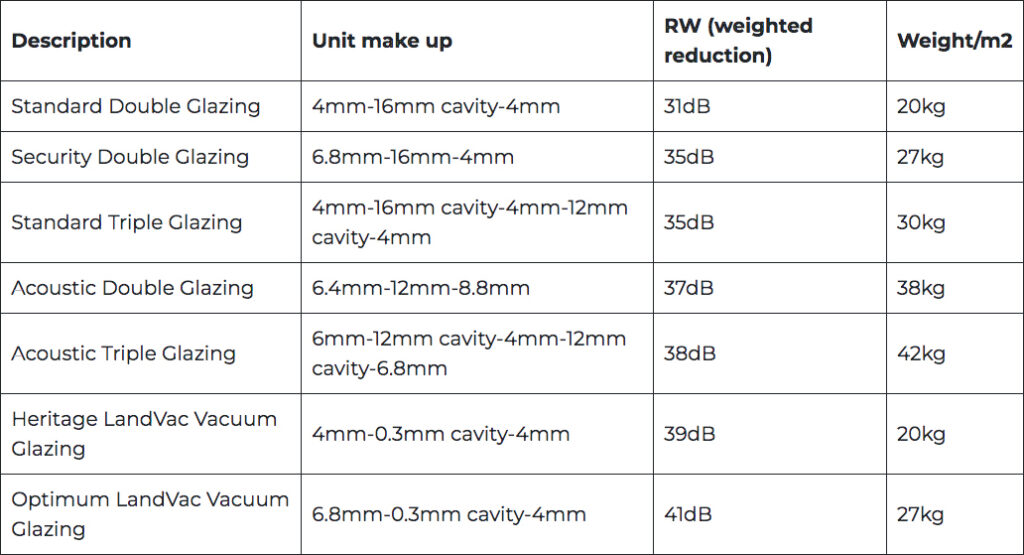

A balanced approach and some typical units

We’ll start by laying out some typical glass units utilised in the industry and how they perform for acoustic performance.

When considering the options above, there are other complications to take into account. For example, most window systems have a limitation on the weight of opening sashes. If you specify a very heavy acoustic unit, then the result might be less opening sashes and smaller opening sashes – which could impact both the indoor air quality and the overall energy efficiency of the products (glass is always the most efficient part of a window and reducing pane size inevitably reduces the overall performance).

Vacuum Glass – best glass for sound reduction?

A vacuum glazing unit is very effective in sound reduction, but also offers a good balance in terms of weight, maximum sizes available and centre-pane U-value. This can be further improved by incorporating a laminated, security outer pane of glass into the unit. When you take this step, the acoustic value far exceeds the performance of even a high specification triple glazed unit.

The further benefit of this approach is that the security pane allows the unit to pass P1A security requirements and therefore, it can be incorporated into properties requiring compliance with Part Q of building regulations. This of course assumes that the basic vacuum glazed unit is toughened, safety glass.

What about the micropillars?

Good question! When we considered the cavity as being a vacuum, we didn’t highlight the impact of the micro-pillars which hold the two panes apart. As you would expect, these small spacers do transmit sound through the unit and reduce the performance of the vacuum glazing in sound reduction; however the impact is relatively small and is considered in the numbers given above. It’s worth mentioning that different manufacturers of vacuum glazing units have different concentrations of pillars, so the units will not all perform the same.

For further information about acoustic properties of vacuum insulating glazing, please see this research paper from 2015 on the subject.

If you have any questions, then please do not hesitate to contact us.